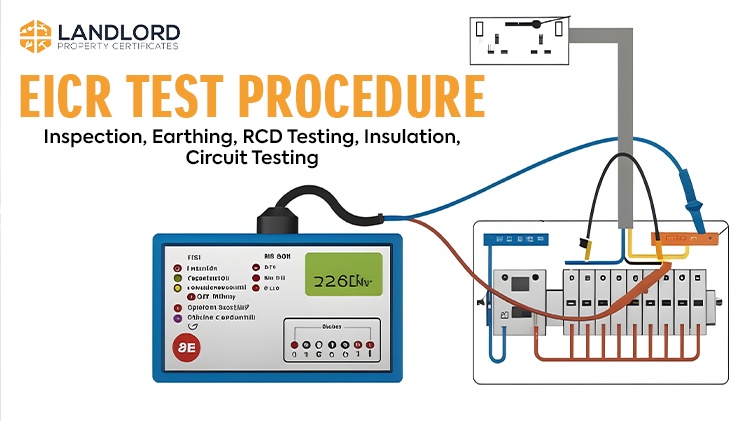

The EICR test procedure checks the safety and functionality of electrical installations to identify potential dangers, check compliance with standards for safety, and prevent electrical risks for any installation. During the EICR process, electricians assign observations to specific categories C1, C2, C3, and FI to ensure that installations comply with safety standards and remain fit for use.

The main steps for the EICR procedure are conducting a visual inspection, earthing and bonding, testing RCD functionality, measuring insulation resistance, verifying circuit continuity, and performing polarity checks to ensure the system’s safety.

The steps for the EICR test remain the same for commercial and residential properties, but the scope changes based on the property type. Electricians conduct more detailed assessments in commercial properties due to complex systems, and in residential properties, they prioritise tenant safety under housing regulations. Rented residential properties require inspections every 5 years or as recommended in the report, while owner-occupied homes need testing every 10 years. Commercial properties demand testing more frequently, typically every 1-3 years.

1. Visual Inspection

Visual inspection is a critical initial step in the Electrical Installation Condition Report (EICR) test procedure and involves systematically examining all visible electrical installations, including sockets, switches, fuse boxes, light fixtures, and distribution boards. Electricians perform a detailed evaluation of specific components during a visual inspection. They assess the consumer unit, checking for issues such as overheating or outdated components. Socket outlets and switches are tested for operational defects, with approximately 34% of outlets showing wear after 10 years and 12% requiring replacement. Earthing and bonding connections are also inspected to ensure proper grounding and compliance, which reduces electrical risks by 47%.

Visual inspection is an essential step in the EICR test, mandated by regulatory standards like BS 7671 (18th Edition Wiring Regulations) and the Electricity at Work Regulations 1989 to ensure compliance and safety. Statistics show that 78% of electrical accidents are preventable through systematic visual inspections. By identifying 62.4% of potential hazards early, this step significantly reduces risks like electrical fires, shocks, and system failures. Non-compliance with this step can result in fines of up to £25,000, making it an essential component of the EICR process.

2. Circuit Testing

In EICR circuit testing, electricians evaluate the safety and functionality of a property’s electrical circuits to ensure they comply with regulations and operate efficiently. Electricians assess insulation resistance to confirm the integrity of wiring insulation, ensuring it meets the minimum resistance threshold of 1 megaohm and detecting 76% of potential failures. They conduct earth fault loop impedance tests to measure how well the system handles short circuits, identifying 72% of electrical risks. During RCD testing, electricians verify that residual current devices trip correctly during faults, preventing 80% of electrical shock incidents. They also confirm wiring accuracy through polarity verification, identifying 42% of potential misconfigurations.

Circuit testing remains mandatory under BS 7671 (18th Edition Wiring Regulations) and the Electricity at Work Regulations 1989. Electricians perform this step to reduce electrical accidents by 82%, mitigate fire risks by 75%, and uncover 94% of hidden defects within the system. Skipping this step leads to severe legal penalties and financial losses, making it a non-negotiable part of the EICR process.

3. Earthing and Bonding

Earthing and bonding play crucial roles in the Electrical Installation Condition Report (EICR) test procedure. Electricians connect electrical installations to the ground through earthing to safely discharge fault currents and prevent electric shocks. Electricians ensure the resistance remains below 1 ohm, with a maximum of 0.8 ohms for residential properties and 0.5 ohms for commercial properties. They inspect the main earthing terminal, external connections, and protective conductor continuity. These evaluations help electricians identify 95% of earthing defects and 76% of bonding vulnerabilities, reducing potential risks and enhancing safety measures.

Earthing and bonding are mandatory under BS 7671 (18th Edition Wiring Regulations) and the Electricity at Work Regulations 1989. Electricians use these steps to prevent electrical shocks, which account for 68% of accidents caused by inadequate earthing. Proper earthing and bonding reduce fire risks by 83% and protect equipment in 88% of cases. Ignoring these steps increases electric shock risks by 67% and causes financial losses, including fines and invalidated insurance.

4. Polarity Check

A polarity check ensures that the live, neutral, and earth wires in an electrical system are correctly connected. This step is critical for ensuring that all equipment and appliances function safely and effectively. Electricians confirm that the live and neutral wires are correctly positioned in outlets, switches, and light fittings. This test identifies 42% of potential wiring misconfigurations, which can lead to equipment damage or safety risks if left unaddressed.

A polarity check is a mandatory step to ensure the correct operation of electrical systems and prevent serious risks like electric shocks and equipment failures. Statistics show that miswiring accounts for a significant portion of electrical hazards, making this step essential.

5. Insulation Resistance

Insulation resistance measures the quality of electrical insulation in wiring and components. Electricians perform this test during the Electrical Installation Condition Report (EICR) procedure to ensure that the insulation effectively prevents current leakage. Electricians evaluate the insulation integrity of cables, circuits, and connected devices. They use a standard test voltage of 500V DC and ensure the insulation resistance meets the minimum acceptable threshold of 1 megaohm. This test detects 76% of potential electrical failures and identifies 64% of hidden vulnerabilities caused by insulation degradation.

Electricians use this step to identify potential faults that could compromise safety or system performance. By preventing issues like short circuits and overheating, insulation resistance tests help reduce fire risks by 75% and prevent 69% of electrical system failures.

6. RCD Testing

RCD (Residual Current Device) testing evaluates the functionality of safety devices designed to disconnect power in the event of a fault. Electricians perform this test during the Electrical Installation Condition Report (EICR) to ensure the devices trip accurately and protect against electric shocks and fire risks. Electricians test the RCD’s ability to disconnect power during earth leakage faults, detecting 89% of potential issues. This step prevents 80% of electrical shock incidents and ensures that RCDs perform effectively under fault conditions.

RCD testing is mandatory under BS 7671 (18th Edition Wiring Regulations) and forms a critical part of the EICR process. Electricians use this step to confirm that safety devices protect users from life-threatening electrical faults.

7. Load Testing

Load testing examines the electrical system’s ability to handle its intended capacity without failure. Electricians perform this test during the Electrical Installation Condition Report (EICR) to evaluate the system under operational conditions. This step ensures that circuits and components can manage the designed load efficiently and safely. Electricians simulate real-world operational conditions to measure the system’s voltage stability and circuit functionality under load.

Load testing is a mandatory component of the EICR process, especially for commercial and high-capacity systems. Electricians use this step to prevent overload conditions that can lead to fire risks or equipment damage.

Labelling and Documentation

Labelling and documentation ensure that all circuits and components are clearly identified and properly recorded. Electricians perform this step during the Electrical Installation Condition Report (EICR) to provide detailed information about the electrical system’s condition and any issues identified. Electricians label all circuits and components, including distribution boards, RCDs, and breakers, for easy identification. They prepare a detailed report documenting test results, risk classifications (C1, C2, C3, or FI), and recommendations for remedial actions.

Labelling and documentation are mandatory under BS 7671 (18th Edition Wiring Regulations). Proper labelling facilitates quick identification during emergencies or maintenance, while documentation ensures compliance with legal requirements and supports accountability.

Who is Responsible for Conducting the EICR for Your Property?

The Electrical Safety First Organisation advises property owners to hire electricians with certifications like City & Guilds 2391 or Part P certification. Certified electricians such as Landlord Property Certificates ensure compliance with regulatory standards and provide a thorough assessment, reducing the risk of accidents and electrical failures.

Electricians perform critical tasks during the EICR process. They inspect visible components for damage, test insulation resistance, verify RCD functionality, and evaluate load capacity. After completing the inspection, they issue EICR safety certificates in Ealing, London, document findings, and recommend improvements to maintain safety compliance. Industry experts emphasise the importance of hiring certified professionals. The Electrical Contractors’ Association (ECA) highlights that qualified electricians detect up to 94% of hidden defects during inspections.

What Aspects Are Not Covered in an EICR Test?

An Electrical Installation Condition Report (EICR) assesses the safety and functionality of a property’s electrical installations. However, it does not include all systems, components, or areas.

Here is a detailed explanation of what electricians exclude.

1. Concealed Installations

Electricians do not inspect hidden wiring behind walls, embedded electrical systems, or underground cable networks during an EICR. They also exclude areas like cavity walls and inaccessible spaces.

2. Specific Equipment Exclusions

Electricians exclude portable electrical appliances, specialised industrial machinery, and temporary electrical systems from the EICR. They also omit fixed electrical equipment not part of the permanent installation, such as external lighting systems.

3. Detailed Technological Assessments

Electricians do not evaluate advanced electronic systems, such as smart home technologies, internet-connected electrical infrastructures, or comprehensive digital networks.

4. Non-Electrical Systems

Electricians avoid assessing non-electrical systems, including plumbing, heating systems, gas connections, structural components, and HVAC systems. These installations require separate inspections for safety and compliance.

5. Complex Technical Evaluations

Electricians do not perform tests for electromagnetic interference, voltage quality analysis, or harmonic distortion during the EICR. They also avoid detailed assessments of power factors and advanced electrical quality metrics.

6. Specific Technological Components

Electricians exclude renewable energy installations, such as solar panels and battery storage systems, from the EICR. They also leave out components like electric vehicle charging points, complex renewable connections, and backup generators.

7. Property-Specific Limitations

Electricians do not cover electrical systems in historic or listed buildings, specialised architectural designs, or custom electrical configurations.

8. External Infrastructure

Electricians exclude utility company connections, street-level electrical systems, and transformer stations from the EICR. They also avoid evaluating the main distribution network as part of the report.

Does the EICR Test Check Every Circuit and Socket?

No, the EICR test does not check every single circuit and socket with 100% comprehensiveness; instead, electricians follow a representative sampling methodology to assess the electrical system’s safety effectively and efficiently. Electricians test 70-80% of electrical circuits and 30-40% of total sockets during the EICR process. They focus on critical circuits and ensure 100% testing of main distribution circuits while sub-circuits undergo sample-based evaluation. Although the EICR does not test every circuit and socket exhaustively, its systematic sampling techniques provide a reliable electrical safety assessment.

How Soon Do You Receive an EICR Certificate After Testing?

You can receive an Electrical Installation Condition Report (EICR) certificate within 2 to 5 working days after the test. Some companies provide same-day or next-day digital certificates for urgent cases, while complex installations may take 7 to 10 working days. Electricians generally do not issue the EICR certificate immediately after the test. They spend time compiling the findings, verifying the results, and ensuring the report complies with BS 7671 standards.

You usually have to wait 3 to 5 working days for a standard certificate. Larger or more complex properties, such as commercial installations, may require 7 to 10 working days. Landlords must provide a copy of the EICR certificate to their tenants within 28 days after completing the test. Tenants living in a landlord’s property should receive the EICR certificate from the landlord within 28 days of the inspection. Tenants can request the certificate if the landlord does not provide it within this timeframe.

Are There Any Prerequisites to Performing an EICR Test?

Yes, certain prerequisites are necessary before performing an Electrical Installation Condition Report (EICR) test. Electricians require clear access to electrical installations, such as consumer units, sockets, switches, and other key components. Removing obstructions, like furniture or appliances, ensures they can perform a thorough inspection without delays. Providing relevant documentation, such as previous inspection reports or records of electrical modifications, helps electricians evaluate the system more effectively.

These steps prepare the property for a smooth and efficient EICR process. To ensure nothing is overlooked, consulting a detailed EICR checklist can provide additional guidance tailored to the property’s specific needs.

What Rules Must Be Followed During an EICR Test?

Electricians conducting an Electrical Installation Condition Report (EICR) must follow strict legal, safety, and technical standards to ensure compliance and reliability. Electricians must hold qualifications such as City & Guilds 2391 and be registered as competent professionals with at least five years of experience.

They must perform mandatory safety protocols, including power isolation, risk assessments, and the use of personal protective equipment (PPE). Electricians also need to compile a detailed report while maintaining data protection standards. For more information, refer to an EICR rules and legal requirements guide to ensure compliance.

Are EICR Tests Cost-Effective?

Yes, EICR tests are highly cost-effective when considering their role in ensuring safety and compliance. While the cost of EICR testing varies depending on the property size and complexity, the benefits of early fault detection, legal compliance, and accident prevention far outweigh the expense. EICR testing typically costs between £150 and £300 for residential properties and more for commercial buildings due to their larger and more complex installations.

Additionally, landlords and property owners can reduce fire risks, prevent electric shocks, and lower insurance premiums by ensuring their electrical systems are safe and compliant.